BENEFITS

SCREWING BOARDS

ONTO JOISTS

EXTREME STABILITY

IN ALL WEATHERS

HIGH

MECHANICAL STRENGTH

REVERSIBLE BOARDS

BOTH SIDES CAN BE USED

REGULAR, EVEN SPACING

BETWEEN BOARDS

ALL YEAR ROUND

EXTREMELY DURABLE

QUICK AND EASY INSTALLATION

40% TIME SAVINGS

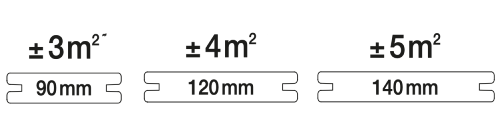

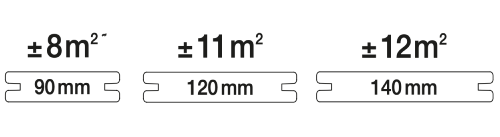

ABSORBS SWELLING

OF THE BOARDS

UNCOMPROMISING QUALITY

AND PERFORMANCE

USE

The invisible SoftWood Clip™ fasteners are designed especially for decking and cladding, in stable treated timber: heat-treated pine, heat-treated ash, Accoya®, Kebony®, bamboo, etc.

SoftWood Clip™ fasteners ensure complete stability over time, along with their high-end aesthetic and unparalleled durability.

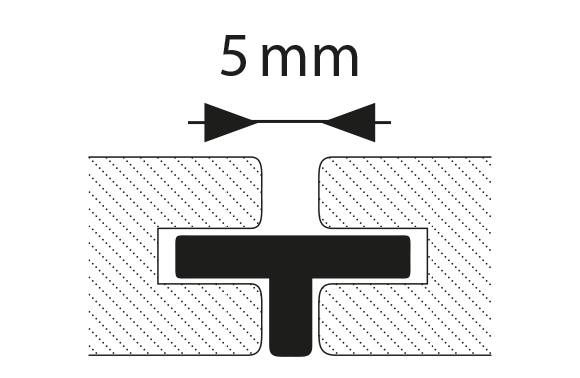

2 SIZES TO GUARANTEE APPROPRIATE SPACING BETWEEN BOARDS

5 mm

M

Spacing between boards during installation

- Max. allowed swelling: 4 mm

- Max. allowed shrinking: 9 mm

- Materials: High Impact Polyamide

- Colour: Black, anti-reflection

- UV resistance

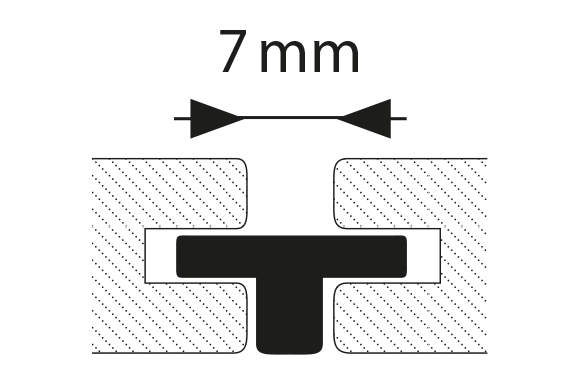

7 mm

L

Spacing between boards during installation

- Max. allowed swelling: 6 mm

- Max. allowed shrinking: 8 mm

- Materials: High Impact Polyamide

- Colour: Black, anti-reflection

- UV resistance

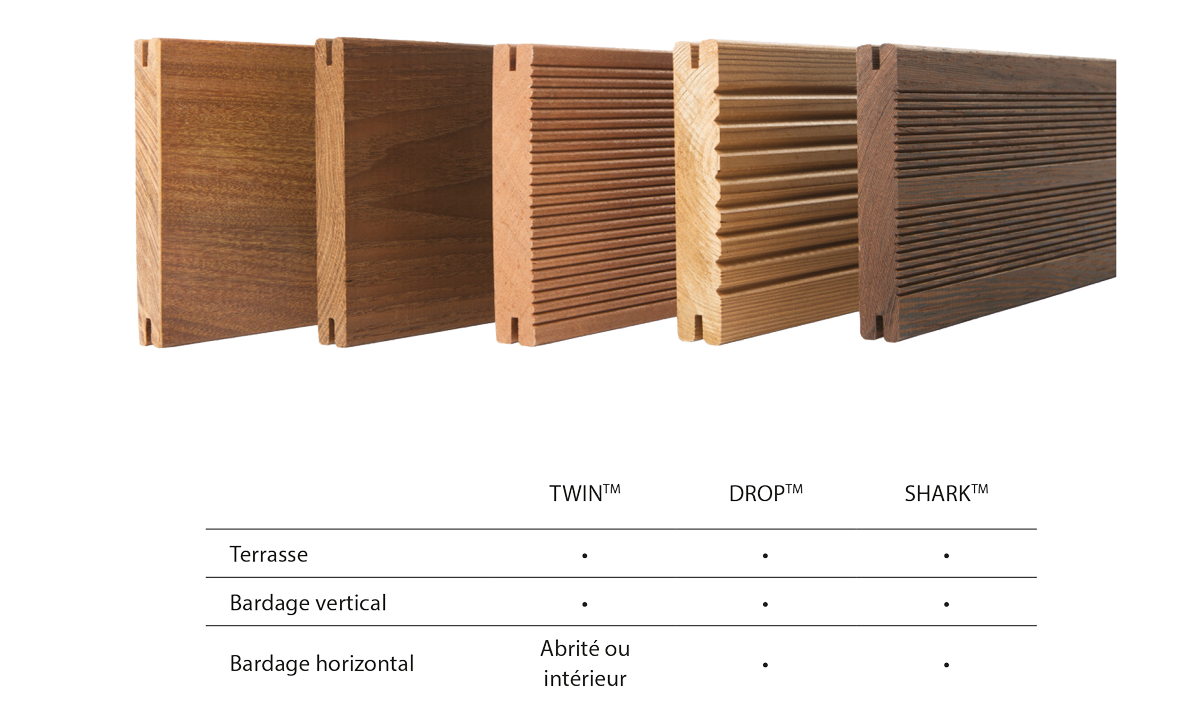

PROFILES

Available in various finishes, thicknesses from 20mm and widths up to 145mm. Other larger sizes, depending on species, thickness, installation conditions, etc.

GROOVING

Grooving along the whole length, with a 4-sided planer or spindle moulder.

Local grooving, with a Lamello® type biscuit joiner or a router.

RANGE

MINI

Available in M (5 mm) and L (7 mm) sizes

CLASSIC

Available in M (5 mm) and L (7 mm) sizes